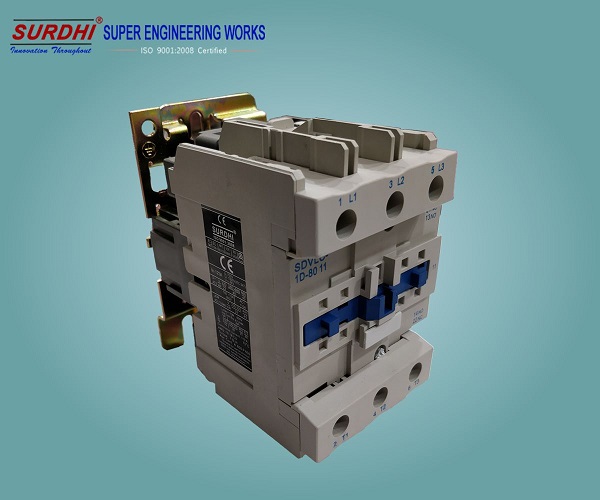

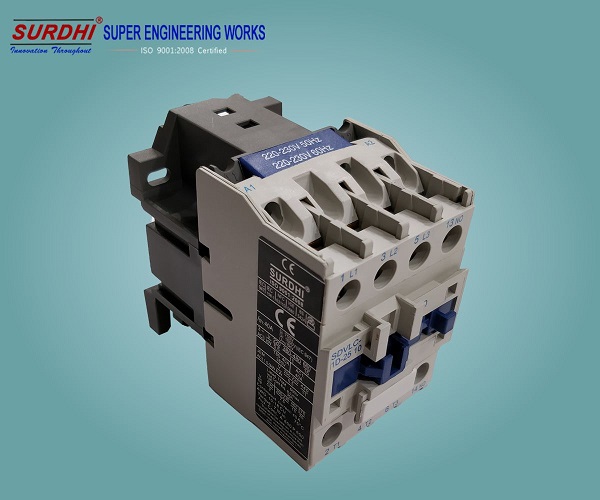

High-power circuits are repeatedly established and interrupted by special-purpose relays called Ac contactors. Ac Contactors control most integral horsepower motors (1 hp and above) and overload heaters in each controlled phase are frequently incorporated by the contactors.

AC Contactors are packaged as per NEMA or IEC standards and IEC devices reduce heat at their contacts through electromagnetic arc quenching techniques whereas NEMA devices heavily rely on mass to dissipate heat from arcing. A typical approach is that the blowout coils which generate a magnetic field designed to push the arc away from the contact area are used with a second set of arcing contacts which is designed to reduce the amount of arcing across the main contacts. Differences in rating practices can lead to IEC devices being smaller by 30% to 70% than their NEMA counterparts.

Overload heaters are often incorporated by contactors in each phase and an assembly or a low-resistance strip of metal is the heater element that heats up as the motor draws current. A normally closed switch will open if the heater temperature reaches a point that corresponds to a moderate overloading of the motor. The opening of the normally closed contact automatically de-energizes the relay as it usually connects in series with the relay coil and powers down the motor.